In today’s rapidly evolving agricultural landscape, precision agriculture is transforming how farmers address age-old challenges like pest control, crop health, and environmental sustainability. At the heart of this transformation lies the science of efficient spraying—an innovation that optimizes pesticide application to maximize yield while minimizing waste. Let’s dive into the key principles and technologies driving this change.

What is Precision Agriculture?

Precision agriculture leverages technology to ensure crops receive the right treatment, in the right amount, at the right time. By integrating advanced tools like drones, sensors, and optimized spraying systems, farmers can increase efficiency, reduce environmental impact, and boost productivity.

One crucial aspect of precision agriculture is the spray application technology, which ensures pesticides reach their target efficiently and uniformly. Both research and practical applications underline the importance of droplet size, spray direction, and application timing in achieving effective pest and disease control.

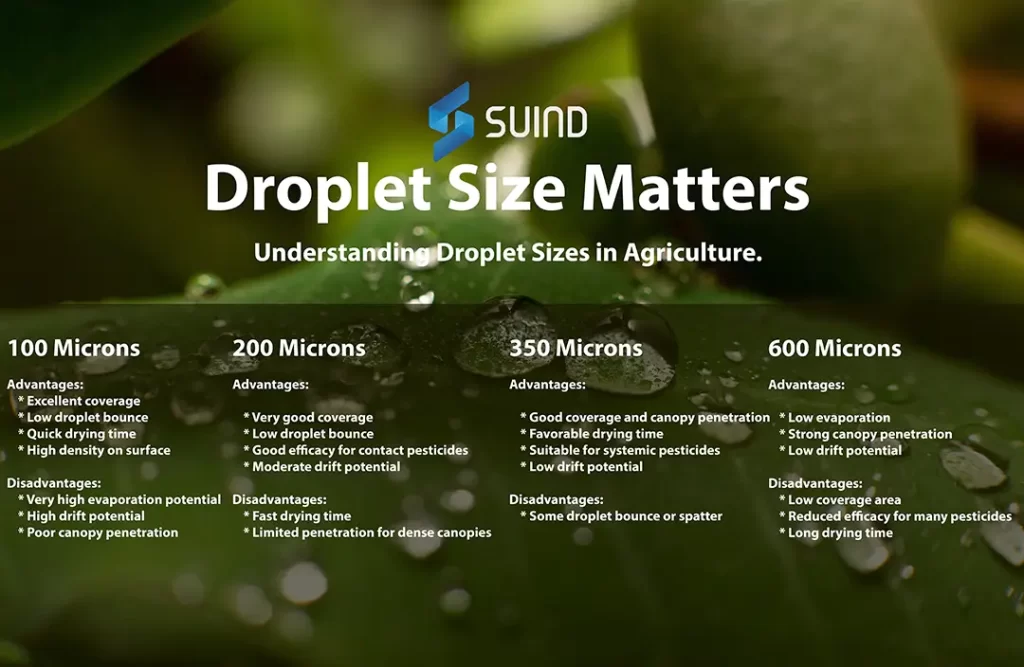

The Science Behind Droplet Size

Droplet size plays a critical role in spray performance and efficacy:

- Too Small (<150 microns): These droplets cover more surface area and provide greater density but are prone to evaporation and drift, reducing effectiveness.

- Too Large (>350 microns): Larger droplets are easier to manage and penetrate deeper but tend to bounce or run off, resulting in waste.

- The Sweet Spot (150–300 microns): Ideal for most pesticides, these droplets balance coverage and retention, ensuring optimal performance.

For example, research into air-assisted electrostatic nozzles shows how adjusting air pressure and charge voltage creates droplets that adhere better to crop surfaces, reducing chemical use while enhancing deposition efficiency.

Traditional Spray Systems: Strengths and Limitations

Knapsack Sprayers

- Strengths: Affordable, portable, and easy to operate, knapsack sprayers are a common choice for small-scale farms.

- Limitations: They lack precision, leading to uneven pesticide distribution, higher chemical use, and increased labor. Additionally, labor is exposed to the used chemicals which can lead to severe health issues.

Tractor-Mounted Boom Sprayers

- Strengths: Suitable for large fields, they ensure faster coverage and better consistency than manual methods.

- Limitations: Boom sprayers struggle in uneven terrains, as maintaining a consistent height becomes challenging, leading to uneven pesticide application. They also risk significant pesticide drift, where small droplets are carried away by the wind, reducing efficiency and causing environmental contamination. This method is also unsuitable for taller crops like maize or sugarcane.

Electrostatic Sprayers

- Strengths: By charging droplets with static electricity, these systems improve adherence to plant surfaces, particularly the underside of leaves, where pests often hide.

- Limitations: While effective in controlled environments, traditional electrostatic systems may lose efficiency in windy conditions or complex terrains.

Centrifugal and Atomizer Nozzles

- Centrifugal Nozzles: Use high-speed spinning to atomize liquid into droplets, creating fine sprays suitable for aerial application. However, they may face challenges with drift control.

- Atomizer Nozzles: Deliver fine, uniform droplets for better coverage but require precise calibration to prevent wastage.

- Drone Integration: Drones equipped with atomizer nozzles, such as SUIND’s Bumblebee, enhance the effectiveness of spray application. By leveraging the drone’s propeller-driven downwash, atomized droplets are pushed deeper into dense canopies, ensuring better penetration and coverage. This system allows for real-time adjustments to spray rates based on drone velocity and prescription maps, ensuring precision application even in challenging terrains.

Innovations in Spray Technology: SUIND’s Approach

While traditional systems have advanced significantly, SUIND’s precision spray system, integrated with the Bumblebee drone, redefines efficiency and effectiveness in agriculture.

How SUIND’s System Works

- Propeller Downwash Interaction: The Bumblebee drone utilizes its propellers to create a controlled downwash, enhancing the penetration of atomized spray into dense canopies. This interaction ensures even the undersides of leaves receive adequate coverage, addressing areas that traditional systems often miss.

- Atomized Spray Precision: Atomizer nozzles use centrifugal force to produce droplets within the ideal size range (150–300 microns). Combining this with propeller downwash improves spray efficiency and deposition accuracy.

- Adaptive Technology: The spray rate is adjusted based on the drone’s velocity and can follow prescription maps for precise applications.

Why SUIND’s Bumblebee Stands Out

- Reduced Pesticide Use: SUIND’s drones use up to 60% less pesticide, lowering costs and minimizing environmental impact.

- Improved Canopy Penetration: Atomized spraying and propeller downwash ensure thorough coverage, particularly in dense canopies.

- Efficiency in Challenging Terrains: Unlike other drones and boom sprayers, Bumblebee adapts seamlessly to difficult and complex terrains, providing consistent application across all landscapes.

- Sustainability: By reducing chemical usage, SUIND not only protects crops but also preserves the soil’s microbiome, ensuring long-term agricultural health and productivity.

Key Factors for Effective Spray Application

Farmers can optimize their spray application by considering the following:

- Pesticide Selection: Choosing the right pesticide based on crop type and pest behavior.

- Spray Timing: Applying sprays during optimal weather conditions to minimize drift and evaporation.

- Application Equipment: Using advanced systems like SUIND’s precision drones for consistent droplet quality.

- Droplet Profile: Maintaining droplet sizes between 150–300 microns to balance coverage and retention.

Real-World Impact

Sugarcane

Outcome: Reduced pesticide costs by 43% with optimized application using SUIND’s drones.

Result: Increased crop yield and reduced chemical runoff.

Rubber Plantations

Outcome: SUIND’s system increased leaf retention by 80% while reducing chemical usage by 60%.

Result: Higher latex output and healthier plantations.

Banana Plantations

Outcome: Farmers achieved a 35% cost reduction compared to manual methods and a 12% increase in production.

Result: Better quality crops with a 20% higher selling price.

The Future of Precision Agriculture

At SUIND, we’re redefining precision agriculture with our Bumblebee drone, combining advanced spraying technology with AI-driven solutions. By optimizing pesticide use, improving spray accuracy, and adapting to challenging terrains, we empower farmers to achieve higher yields while reducing costs and environmental impact.

SUIND’s Bumblebee drone is not just a tool—it’s a step toward sustainable farming practices. With innovations like propeller-driven downwash, real-time adjustments, and minimized drift, we’re making precision agriculture accessible to farmers worldwide. The future of farming isn’t just about feeding the world; it’s about doing so responsibly, sustainably, and efficiently. The future is here, and it’s flying with Bumblebee.